"The 533i was the fastest sedan sold in the USA in 1983." - Wikipedia

Today, it's only the fastest when I'm trying to get home before the engine quits or something else threatens to leave me stranded on the side of the road!

Features/specs

The E28 page on Wikipedia gives a good overview of the basics of the E28 series - E28 refers to the chassis on which a number of BMWs were built in the 80s. Some of my favorite features in this car are:

- The 3.3L inline 6-cylinder engine. Man, do these things run smooth, even with 300k miles on them. (and a little work)

- Rear wheel drive. It may not be the safest in the snow, but at least it's fun!

- 5-speed manual transmission

- 4-wheel disc brakes

- Goofy computer and electronic stuff everywhere. More on this later.

My car also has a couple of upgrades taken from an M535i

- Getrag 265 transmission (the one with the removable bell housing)

- 3.73 limited slip differential

These along with the 533i flywheel -- which is the lightest (non-custom) one available for this series of cars -- and manual seats... well, it's a light e28 with an aggressively-geared drive drain and it makes other people try to talk me into racing it.

Work that's already done

I pretty much went through the whole engine compartment between 2003 and 2006 and replaced the drivetrain between 2006 and 2008.

My goal with the engine was to replace the seals, gaskets, and hoses in order to get rid of any fluid leaks and reduce the possibility of more occurring in the future. I haven't seen any oil or coolant under the car, but it did spring a hydraulic fluid leak where the hydraulic fluid hose connects to the break booster... the only hose I didn't replace.

I had the head cleaned up and the valves and valve seals done at The Engine Shop in Longmont, CO. Sadly, they don't have their own web page, but here's Google's link for them.

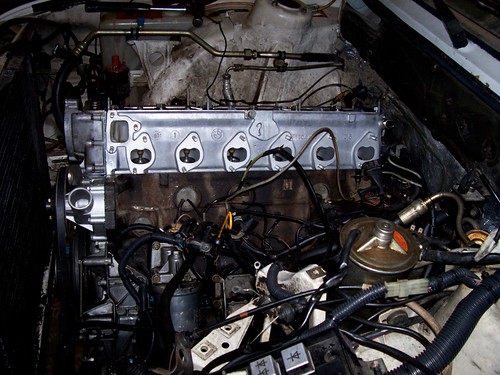

Here's a good picture of the intake manifold, which I cleaned up myself.

One of the bigger challenges was getting the transmission high enough off the ground to mate it up with the engine. I accomplished this with a ramp made out of some old 2x4s, a floor jack, and some scrap wood. I was able to put the transmission at one end of the ramp, lift the other end up and sneak the jack under it, slide the transmission forward so it was at the end near the jack, then jack it up to the level of the engine. I used scrap wood as shims under the low end of the ramp to get the ramp angle matched up to the angle that the engine was sitting at. From there, I pushed the transmission forward and wiggled it around until the input shaft engaged with the engine.

I have cut a few of my own gaskets. The one below is for the plate on the back of the head. You can see where the old one had failed on the right.

The shift console -- the assembly that holds the gear shift level in place -- for the Getrag 260 transmission originally on the car wasn't compatible with the 265 transmission, so I crafted my own. Below, you're looking at the shift level without a knob on it, and the shift console with sits on tip of the transmission, underneath the car.

Some sort of insect nest on my old differential:

The bracket on the back of the 3.73 differential (3.73 is a gear ratio, BTW) didn't line up with the bolt hole on the car, so I had to swap the plates on the back of the two differentials.

You can see the differences here:

...and here's the new diff with the subframe and half shafts attached, ready to go back into the car:

Speaking of the subframe, I also managed to replace the subframe bushings. People have done this without removing the subframe from the car, but after removing one bushing and not being able to get the new one in, I thought it would be easier if I could get the whole thing off the car and move it to where it was easier to work on. I removed the subframe and clamped it to my work bench. I used a coping saw to cut up the old bushing:

I needed to to back the new (stuck) bushing out of the subframe -- obviously, sawing it up wasn't going to work here. I found a big socket at Sears that I used to distribute the force around the edge of the bushing (where, previously, the puller was just applying force to the middle,) and used that to push it out of the subframe. This might have been easier than sawing up the old ones had I known how to do it.

And... finally, in March of 2009, the car moved under its own power. Here it is in the driveway of my apartment in Denver.

In 2009, I replaced the main board in the instrument cluster but didn't take any pictures. This fixed a problem with my temperature gauge jumping around when I hit bumps in the road. The interesting thing here is that, in contrast to what my original hypothesis was, my temp gauge problem wasn't a wiring problem, but appears to have been be a board problem. We'll keep that in mind as we move forward.

Current status

I currently have the dashboard removed and am isolating a rattle in the ventilation system. It's a little odd -- it occurs at 3000 RPM, but only when the car is moving! Of course, when I started taking things apart that were hidden in/under/behind the dash, it became obvious that every bit of foam in the car was disintegrating. In this case, it's a lot of weather-stripping-type stuff used to keep the ventilation system from leaking and losing air pressure. This isn't a big issue, but it would be nice to have adequate air pressure for the heat in the winter.

Like my temperature gauge, the warning lights turn on and off while I'm driving. BMW calls the system "active check," but what it amounts to is that there are relays and sensors all over the car that are constantly checking the light bulbs, fluid levels, and fluid pressures. If something goes wrong, a warning light comes on. Something is clearly wrong! (Just not what it says.)

There's some sort of trip computer in the car, and mine appears completely dead. I'll try to get a picture. If it weren't so retro and cool looking, I'd find a way to stick an iPod or iPhone in the space it's occupying, but I can't get over the 80s-ness of the whole thing. 7-segment display and a phone-style keypad! I'll have to find another spot for my iPhone... maybe I can stick it in the glove box and control it through the 1983 interface.

Oh yeah - no stereo.

Ugly purple window tint.

The driver seat is ripped and the foam inside has collapsed.

Headlights need to be aligned. They also seem too dim.

The AC doesn't work and blows its fuse when I turn it on.